It's hip to be square... well, your CNC Machine's spindle at least...

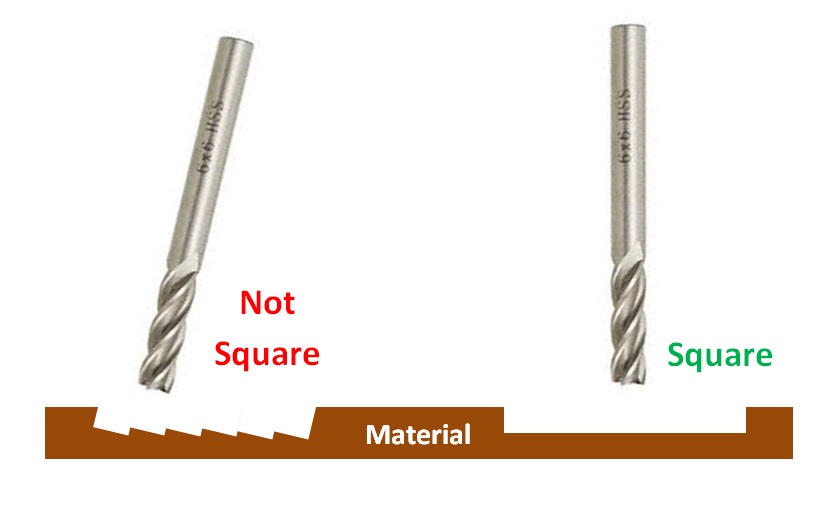

While doing some pocketing cuts on the CNC Router, the bottom surface of the pocket turned out a little bit ragged. This is caused by the router’s spindle not being perpendicular to the machine bed. Instead of a flat bottom, it was ‘saw-toothed’, the size of the ‘teeth’ being a function of the cutting tool diameter, the offset distance between passes and how out-of-square the spindle is to the bed. Click ‘continue reading’ below to see an exaggerated graphical example. This is not a unique problem and there is definitely a solution. There is a thing called a tramming gauge. It is super simple: a piece of metal that holds an indicator a certain distance from the spindle. The tramming gauge is loaded into the spindle and a measurement is taken in one position and again after the tramming gauge is spun 180 degrees. If both measurements are the same, the spindle is square. Here’s a great video on Tramming a Bridgeport Milling Machine Spindle.

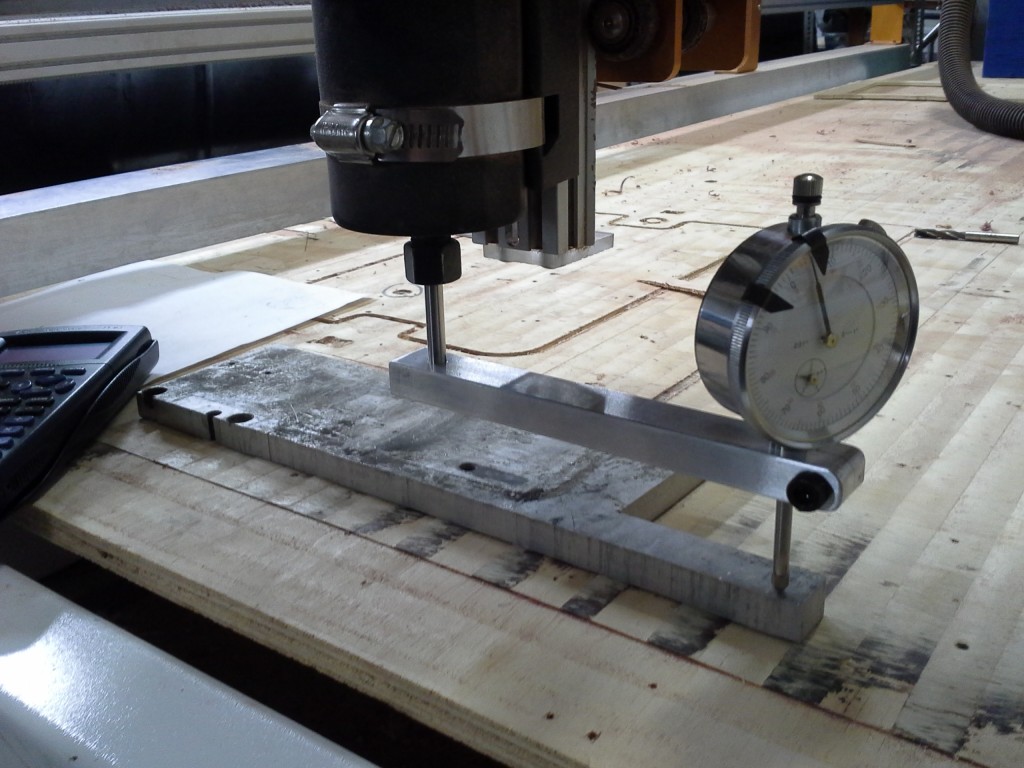

We didn’t have a tramming gauge so we made one. The main beam is 1/2 x 3/4” aluminum stock. Since the CNC Router has a 1/4” collet, a ground 1/4” rod was press fit into a hole drilled in one end of the bar. Another hole, 5 inches away, was drilled to accept the indicator. A slot was cut from the end of the bar to the hole so that the indicator could be tightened in place via a hole drilled and tapped for a cap screw. So, over the 10 inch swing diameter, there was about 0.070” of difference in measurement. Too much, indeed! Correcting it is as simple as loosening the spindle, re-positioning it closer to square and re-tightening the hardware. This process is repeated until both readings 180 degrees apart are the same.